Plastic Injection Molding Services

Polyfab LLC integrates the latest plastic injection molding technology to manufacture the highest quality parts at the most competitive prices possible. We achieve lean efficiency through cellular manufacturing processes that include our complete injection molding services as well as assembly, drilling, welding, and value-added services, like part decorating and custom packaging.

Capable of lights-out, 24/7 around-the-clock production, Polyfab’s highly versatile plastic injection molding capabilities allow us to meet our customers’ most challenging requirements. We strive to exceed all expectations in quality, consistency, and turnaround time, all while establishing a more robust supply chain through superior American manufacturing solutions.

Our Facility: Clean Cell Molding Class 100,000 on 39-, 55-, 140- and 200-ton Presses

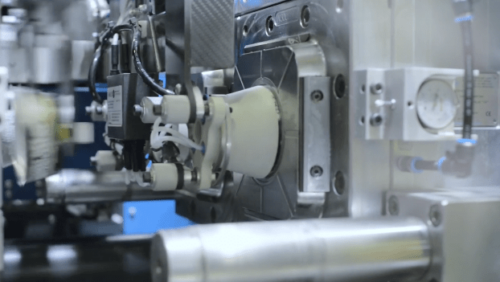

Polyfab’s state-of-the-art facility includes Class 100,000 cleanrooms for our 39-, 55-, 140- and 200-ton presses. Our injection molding department includes numerous additional presses rated up to 720-ton and 140-ounce capacity. We utilize extensive automation capabilities to facilitate a more efficient and repeatable injection molding process in accordance with ISO 9001:2015 quality control standards.

Automated Injection Molding Solutions

Polyfab’s automated injection molding services utilize Yushin and Fanuc robots along with custom designed end-of-arm fitments. We can even provide product-specific custom automation solutions to better accommodate each customers’ unique requirements.

Our automated equipment solutions yield better manufacturing consistency, higher productivity, and an overall improvement in the quality of our products. Automation especially improves cost-effectiveness for high-volume production runs that can take advantage of our lights-out manufacturing plans.

Presses – Up to 720 ton and 160 oz

At Polyfab, we utilize 39-ton to 720-ton capacity machines reaching up to a 160-oz capacity. All of our machines are equipped with robots for automated operations.

- Toshiba, Engel, Krauss Maffei, Nissei, JSW

- Controls on Presses – Process Monitoring

- Kistler (Cavity Pressure)

- Clean Cell Molding Class 100,000 on 39-ton and 140-ton presses

Plastic Injection Molding Materials

Polyfab has the capability to mold a wide range of thermoplastic resins and other materials:

- Polypropylene

- Polyethylene

- A.B.S

- Polystyrene

- Polycarbonate

- Acetal

- Nylon

- Chemical blowing agent

- Antimicrobial additive

- Custom blends and fillers on request

Turnkey Product Assembly

Polyfab can supplement our full-service injection molding capabilities with turnkey product assembly. From design to delivery, we offer our clients a streamlined production solution that provides completed products on schedule in the exact quantities needed.

Our injection molded product assembly services include:

- In-cycle assembly

- Post-mold component assembly

- Custom bar coding

- Recycle program

- Automated palletizing without corrugated boxes

- Secondary machining

Our value-added assembly services are accomplished through cellular manufacturing, including all assembly, drilling, welding, decorating, and/or custom packaging operations to meet each customer’s unique requirements.

Our Scientific Approach to Problem Solving in Custom Manufacturing

Our custom molding process is developed using a systematic, data-driven approach. Those conditions that prevent necessary process controls are first identified and corrected. Then, a robust, repeatable manufacturing process can be established and defined by meaningful plastic conditions, independent of machine settings.

Polyfab is staffed with a Master Molder Certified Process Technician on every shift. Communication between technicians takes place using common terminology regarding specific process inputs and outputs. Because of this, problem solving is a systematic procedure structured around defining the root cause, with actions taken based on knowledge of the process.

Some of the tools Polyfab uses to drive process control and improvement through meaningful data include:

- Kistler “CoMo” cavity pressure sensing

- RJG “eDart” cavity pressure sensing

- IQMS Real Time Machine Monitoring

- Our Outstanding Team of Highly Experienced Employees

Quality American Injection Molding Services Since 1971

For more than half a century, Polyfab has remained one of the nation’s leading plastic injection molding companies. Our mission is to provide the highest quality custom molded products possible – manufactured to each customer’s exact specifications right here in Sheboygan, Wisconsin, and delivered on-time, every time.